Pendulum Type Governor

Pendulum Type Governor

The governor system is like a cruise control system. It maintains the speed of your lawn mower or outdoor power products. When Briggs & Stratton governors are adjusted properly, they keep your speed steady regardless of engine load – the amount of work the engine must perform.

A car speed governor, or speed limiter, is a device that sets and limits a car’s top speed. When a car that is fitted with a speed governor reaches a preset top speed, the device begins to curtail combustion and limits the supply of fuel and air to the engine.

Pendulum Type Governor:

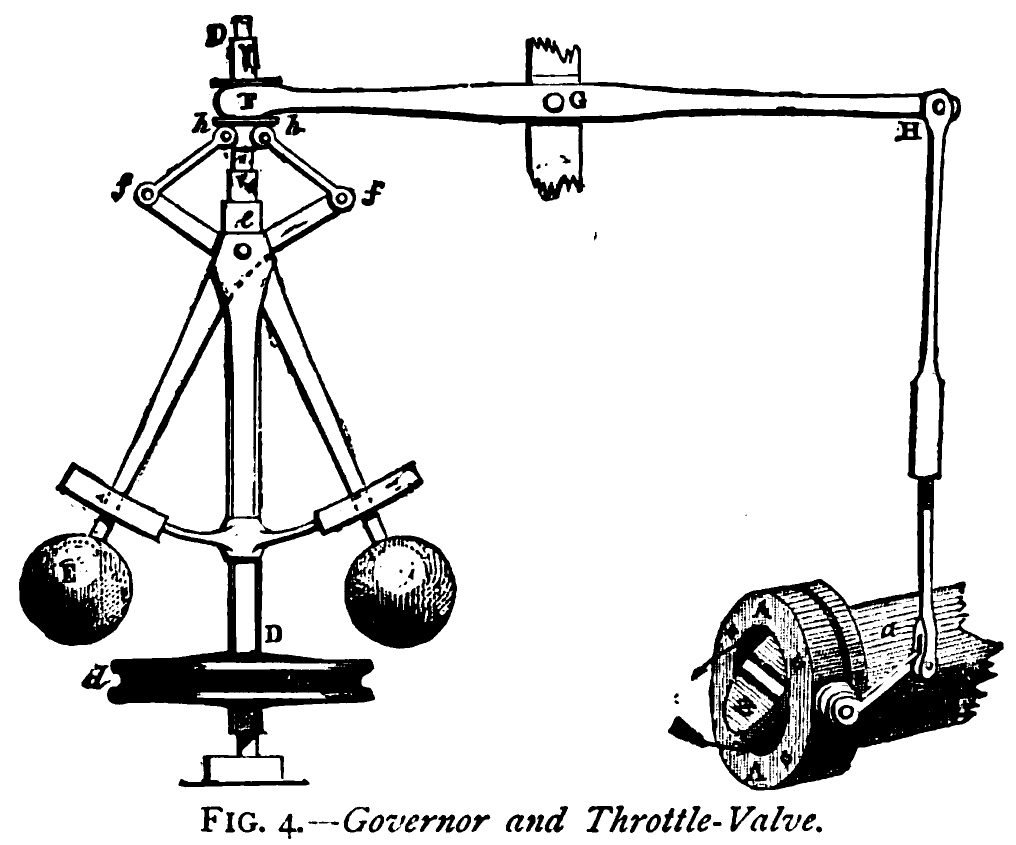

Centrifugal governors are used to balancing the rotating balls by using the centrifugal force. Two balls with equal mass are attached to the arms, they are called as fly balls or governor balls. With the help of spindle, balls rotate and the engine is driven by the bevel gear. To the spindle upper end arms are joined, when the balls are revolving about the vertical axis they move up and down.

Centrifugal governors are used to balancing the rotating balls by using the centrifugal force. Two balls with equal mass are attached to the arms, they are called as fly balls or governor balls. With the help of spindle, balls rotate and the engine is driven by the bevel gear. To the spindle upper end arms are joined, when the balls are revolving about the vertical axis they move up and down.Pendulum governor

Watt Governors:

Balls are arranged on the two arms and the upper arm is connected to the spindle and lower arm is connected to the sleeve. Watt governor is used in the steam engine by James watt. With the help of the output shaft the spindle is driven.

Working of Watt governor

Watt governor is the simplest and gravity controlled form of the centrifugal governors. It consists of two fly balls attached to the sleeve of negligible mass. The upper sides of arms are pivoted so that its balls can move upward and downward as they revolve with a vertical spindle. The engine drives the spindle through bevel gears. The lower arms are connected to the sleeves. The sleeve is keyed to the spindle in such a way that revolves with the spindle. At the same time, it can slide up and down according to the spindle speed. Two stoppers are provided at the bottom and top of the spindle to limit the movement sleeve.

- In the case of watts governor, the controlling force is provided by the action of gravity, at uniform speed controlling force is equal to the centrifugal force, and it balances each other.

Pinned, Open arm and Crossed arm type Watt governor

[Describe open and crossed arm types Watt governor?]

The Watt governor is classified into three based on the position of upper arms. The arms can be connected in following three ways.

a. Pivot is on the axis of spindle

b. Pivot is offset from spindle

c. Pivot is offset, and arms cross the axis.

The Watt governor is classified into three based on the position of upper arms. The arms can be connected in following three ways.

a. Pivot is on the axis of spindle

b. Pivot is offset from spindle

c. Pivot is offset, and arms cross the axis.

Simple pinned: The upper arms are joined to a point “O” on the axis of the spindle, where both arms intersect the spindle axis.

Open arm type: Instead of connecting directly to the spindle, the upper arm of Watt governor is hinged on a collar attached to the spindle (or joined by a horizontal link) as shown in fig b. The arms when produced meets the axis of the spindle at O.

Crossed arm type: The upper arms o governor in hinged on a collar on the axis of the spindle (or arms are joined through a fixed horizontal link) as shown in fig c. The arms intersect the axis at a point O.

Open arm type: Instead of connecting directly to the spindle, the upper arm of Watt governor is hinged on a collar attached to the spindle (or joined by a horizontal link) as shown in fig b. The arms when produced meets the axis of the spindle at O.

Crossed arm type: The upper arms o governor in hinged on a collar on the axis of the spindle (or arms are joined through a fixed horizontal link) as shown in fig c. The arms intersect the axis at a point O.

Limitations of Watt governor

- Watt governors are limited to in vertical position applications.

- Watt governor is used in very slow speed engine. At higher speed, the sensitivity will decrease.

Limitations of Watt governor

- Watt governors are limited to in vertical position applications.

- Watt governor is used in very slow speed engine. At higher speed, the sensitivity will decrease.

Watt governor height equations and calculations

m = Mass of the ball, kg

w = Weight of ball, N

h = Height of the governor- the vertical distance between the center of the ball and a point O, where the arms meets the axis of the spindle, m

r = Radial distance of balls from the axis of the spindle, m

ω = Angular velocity of the balls and arms about the spindle axis, rad/s

T = Tension in the arm, N

It is assumed that the sleeve is frictionless, the weight of links/ arms is negligible. Now the ball is in equilibrium under the action of the following force

w = Weight of ball, N

h = Height of the governor- the vertical distance between the center of the ball and a point O, where the arms meets the axis of the spindle, m

r = Radial distance of balls from the axis of the spindle, m

ω = Angular velocity of the balls and arms about the spindle axis, rad/s

T = Tension in the arm, N

It is assumed that the sleeve is frictionless, the weight of links/ arms is negligible. Now the ball is in equilibrium under the action of the following force

- Centrifugal force acting on the balls, Fc = m ω2 r

- The weight of balls, w = mg

- Tension in the upper arms, T

There is no tension in lower arms because it is assumed the sleeve is frictionless and weight of arms are negligible.

OR

Take moment of these forces about O.

For equilibrium

Take moment of these forces about O.

For equilibrium

Sleeve lift equal to 2 (h2 – h1)

h1 sleeve position at speed N1

h2 sleeve position at speed N2

h1 sleeve position at speed N1

h2 sleeve position at speed N2

- The height of the ball is independent of the mass of the ball, it only depends on the speed of the spindle.

- At higher speed, the sensitivity of watt governor will decrease.